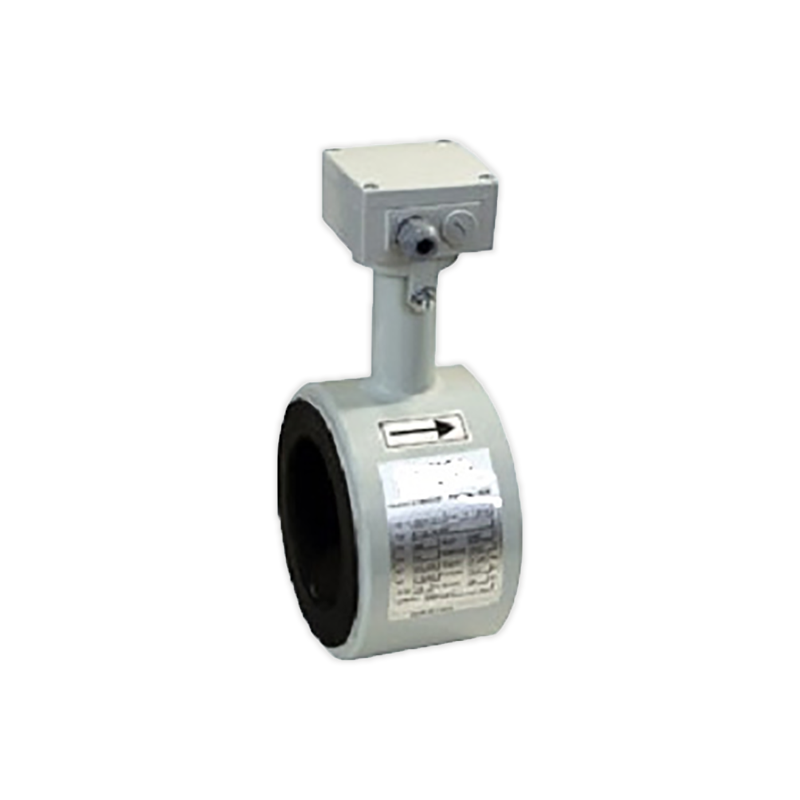

Available in remote or integral options the Smart Storm Flow S3000 series of induction flowmeters are designed for highly reliable flow measurement of conductive liquids.

Available in remote or integral options the Smart Storm Flow S3000 series of induction flowmeters are designed for highly reliable flow measurement of conductive liquids. They meet exacting requirements for accuracy and long-term stability and are available with a variety of electrode lining for use in different industries including food, chemicals and waste water. Because induction flow meters have no moving parts and have no hydraulic influence on the pressure conditions within a pipe they are the preferred method for flow measurement in closed pipes. The Flow S3000 induction flow meter will measure flow in both directions and is available with either integral or remote IP65 rated backlit display. Outputs include pulse, frequency and 4-20mA and serial data transfer is via RS232 or RS485. The Flow S3000 series is an extremely rugged instrument for use in hostile environments and is particularly simple to both install and programme. Coupled with its low maintenance requirement the Flow S3000 is the ideal solution for industrial flow measurement in closed pipes.

Features

- Wide measurement range up to 12m/s

- Integral or remote display

- Simple user-friendly programming

- Temperature operating range up to 150 0C

- Self cleaning electrodes

- Liners-Hard rubber (TG) Soft rubber (MG), Special rubber (NG), PTFE (T)

- IP66 or IP68 Sensor

- Rugged construction

- Low maintenance

- Long life product

Applications

- Trade Effluent Flow

- Waste Water Flow

- Chemical Flow

- Drinking Water Flow

- Wide range of Application Industries including Food, Chemical and Pharmaceutical

Sorry no download is available at the moment

There is currently no videos available for this product.

Mag Flow meters are used to measure liquid flow in closed pipes. Only conductive liquids can be measured so for example oils could not be measured.

The flow meter consists of a sensor which forms part of the pipe and a programmable display.

The display can either sit on the sensor (integral) or be remotely located up to 50m away. You need to make this choice.

If your pipe is likely to be submerged you need to choose the IP68 remote display option.

You need to decide on the pipe size and the pipe fitting (either flange or wafer) and the length of cable between the USI display and mag flow sensors. If you only want 1 sensor select none for the 2nd choice field.

If your pipes are plastic you must order earthing rings else the sensor will not work. These are not required if your pipe is metal.

Hard rubber lining is suitable is suitable for most applications up to 90 0C but for higher temperature up to 1500C and aggressive chemicals PTFE should be chosen. and sanitary linings are available on request. For sanitary use choose PTFE DIN 1851.

Communications

If you require communication outputs to other equipment such as a 4-20mA to a data logger you must add this as an option otherwise choose none.

Likewise, if you require a relay to activate an alarm or trigger a waste water sampler this is an option otherwise choose none.

Empty pipe detection

Normally mag flow meters are installed such that the pipe is flooded at all times. If this cannot be guaranteed the meter will run erratically when air is in the pipe. If this is a likely scenario then add empty pipe detection as an option.

Electromechanical Cleaning

If the liquid being measured is likely to build up on the walls of the pipe such as grease or fats then over time the flow meter will read a higher flow than it should. it is in these applications it advisable to add Electromechanical Cleaning as an option. This periodically send an electromechanical wave thorough the pipe linning to dislodge any build up and ensure the sensor is clean at all times.

Explore our other products

Click on a category for more details.