With over 30 years of experience in effluent management, Smart Storm understands effluent and effluent plants. We work with companies to design and install cost-effective solutions andprovide ongoing environmental partnerships.

Additionally, payback on effluent plants is often achieved within 12 to 18 months, and Smart Storm can offer lease finance packages to spread the cost, making it a worthy wastewater investment to consider.

Industries that benefit from wastewater treatment

- Food and Drink

- Abattoirs

- Dairy

- Pharmaceuticals

- Chemical

- Textiles

- Agriculture and Aquaculture

- Aerospace

- Metal Processors

- Mining

- Energy

- Construction

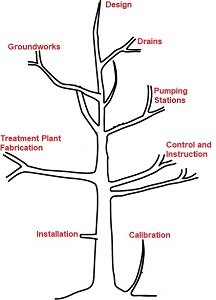

Smart Storm Total Solutions

Smart Storm specialises in Industrial wastewater solutions and offers a one-stop-shop for Treatment plants including:

- Design

- Project Management

- Groundworks

- Drains

- Pumping stations

- Treatment Plant Fabrication

- Control and Instrumentation

- Installation and calibration

Why do I need an Effluent Treatment Plant?

Did you know that all industries require a consent from the water company to discharge their industrial wastewater into the sewer?

When discharging into land, river or sea this consent is governed by the Environment Agency (England), Natural Resources Wales or SEPA (Scotland).

The consents determined by these authorities will set the limit on several wastewater parameters that your effluent must not exceed.

Failure to control your discharge can lead to fines or even factory closure. The installation of an effluent treatment plant will ensure you meet these legal consents and often leads to reduced water bills.

Your consents will always set limits on the suspended solids in your industrial wastewater, as well as the volume of COD (Chemical Oxygen Demand) in the water and the pH.

There may be other parameters depending on your industry, like the measurement of metals, fats, oils and grease (FOG) and chemicals like Nitrates, Phosphates, Ammonia, Sulphates etc.

Your consent will also put a daily limit on trade effluent volume (m3) and its maximum flow rate in L/s.

What is COD?

In simple terms, Chemical Oxygen Demand (COD) is the amount of dissolved oxygen that must be present in water to oxidise organic materials, like fats, oils and food waste.

Therefore, the greater the COD, the smaller is the oxygen concentration in the wastewater. Oxygen depletion has an environmental impact and can lead to suffocation of Aquatic and marine life.

To reduce COD water pollution, water companies must ensure that the industrial wastewater entering the watercourse (river or sea) has an acceptable level of oxygen concentration.

This is done in aeration basins and is one of the largest operational costs for water companies.

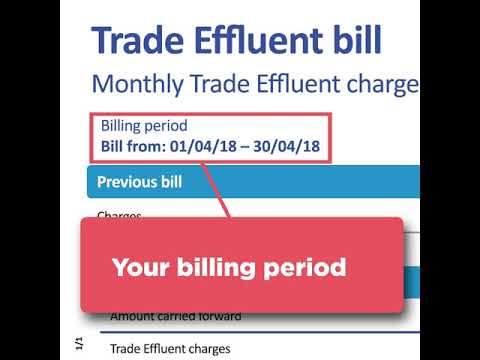

How is my Trade Effluent Bill Calculated?

The Mogden formula is an industry wide formula used to calculate trade effluent charges. The formula compares the strength of the trade effluent discharged with standard domestic sewage. Trade effluent strength is directly proportional to the COD and Settled and Suspended Solids in your trade effluent discharge. So, effluent that is weak in strength such as vehicle washing, cooling or rinse water requires less treatment and will be charged at a lower rate than higher strength trade effluent for example from food manufacturing or Pharmaceuticals,

Textiles etc. This is because at the receiving water company treatment plant it costs more money to reduce COD and Suspended solids in high strength trade effluent before it can be legally discharged into the watercourse (sea or river).

The Mogden formula calculates the pence per cubic metre that you will pay, and your total bill is the volume of trade effluent discharged over a period time the Mogden unit charge. So, if your Mogden charge is £1.50 per m3 and you discharge 100m3 a day your daily trade effluent bill will be £150 per day.

How can I reduce my Trade Effluent Bills?

Install a Smart Storm Effluent Treatment Plant!

In doing this not only will you ensure you meet your legal consent compliance, but you will also reduce your COD and suspended solids measurements which together account for 60-70% of your trade effluent bill.

Type of Plant we Supply

Biological Wastewater Treatment Plants

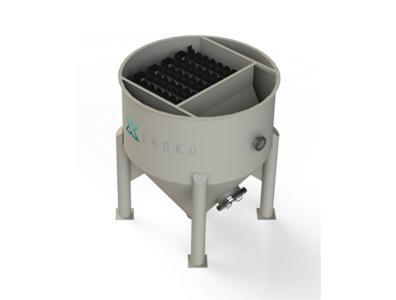

Smart Storm specialises in bioaugmentation treatment plants. These are similar to SAFF plants but use targeted aerobic bacterial strains to enhance the efficacy of the plant.

To achieve this, we select powerful natural biological products that target bacteria and enzymes to break down organic compounds in the effluent treatment process.

This usually takes place in a large, aerated retention tank.

Petroleum, food and drink, agriculture, and hazardous waste industries have high organic loads which are easily digested by our powerful bacteria to reduce COD, suspended solids and target substances such as fats, phenols, sugars, starches and sulphates in the effluent treatment process.

The 100% natural products we use in our bioreactors are also extremely efficient at reducing unpleasant odours in effluent treatment plants.

Using our bioreactors in your effluent treatment plant saves you money, improves the environment

and reduces your carbon footprint.

Dissolved Aeration Flotation (DAF) Plants

DAF plants use chemicals, aeration and mechanical scrappers to remove dissolved and suspended solids, oils and grease from wastewater streams.

They can be up to 90% efficient but are unsuitable for liquid only applications.

The feed wastewater to the DAF float tank is often (but not always) dosed with a coagulant (such as ferric chloride or aluminium sulphate) to coagulate the colloidal particles and/or a flocculant to conglomerate the particles into bigger clusters.

The wastewater is then fed into a flotation tank where white water (pressurised aerated water) consisting of microbubbles attaches to the solids in the effluent stream which float to the surface which is then removed by a skimmer.

How Effective are DAF systems?

For trade effluent treatment where solids form a large part of the effluent stream, DAF systems are highly efficient and can reduce COD by up to 80%, solids by up to 90%, and fats, oils, and greases by up to 95%.

Additional Treatment Plant We Provide

Often it is necessary to install additional plants to successfully treat the effluent to meet the consent parameters.

We take a wholistic approach to designing an effluent plant to ensure it meets the needs to ensure regulatory compliance and bill reduction.

Wedge Wire Screens

Wedge wire or run-down screens are ideal for pre-screening out solids before they reach the treatment plant. They have no moving parts, self-clean and require little or no maintenance.

They work by pumping wastewater over a parabolic perforated screen, which is between 0.125mm to 4mm.

This allows water to flow through the screen into a collection chamber whilst the solids remain on top.

Consecutive pumping cycles push the solids down the screen which then fall into a collection hopper.

FAQs

How does an aerobic biological wastewater treatment plant work?

Treating industrial wastewater with an aerobic process is a biological method that uses oxygen to break down organic contaminants like nitrogen, starch, fats and oils.

We analyse your effluent stream and then produce a blend of bacteria that will target and digest the organic materials in your wastewater.

As Aerobic bacteria require oxygen to survive, oxygen is continuously pumped into the reactor tank.

The bacteria use the organic matter as a food source to convert it to carbon dioxide and water. As a result, the pollutants, COD and suspended solids are removed from the effluent stream.

Are Biological Wastewater treatment plants more effective than DAF plants?

Along with solid screening, biological treatment plants are comparable to DAF plants. However, in industries that contain few solids in their waste discharge, much of the organic load that contributes to the COD is in the solution, so only Biological treatment plants will work in these industries.

Are Biological Wastewater Treatment Plants cheaper than DAF plants?

Yes! They are also less complex than DAF plants, have no moving parts and require little maintenance.

Watch our industrial pH balancing video below

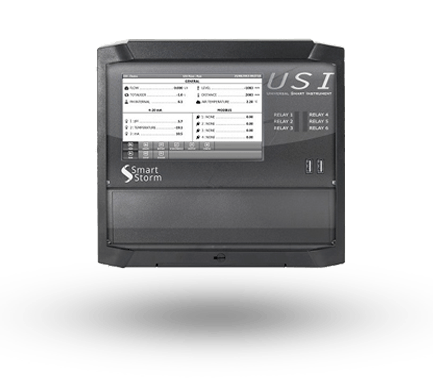

Intuitive Monitoring

In our installations we use our range of monitoring instruments. They utilise the latest technologies. Therefore offering a truly user friendly experience for effluent management and monitoring in your effluent plant.